PEPI YA TŠEPE EA KHABONE KHABONE E SEAMLLES TŠEPE PIPE

Tlhaloso

Seamless Steel Pipe e entsoe ka tšepe e chitja e tiileng 'billet' e futhumatsang le ho sututsoa kapa e huleloa holim'a foromo ho fihlela tšepe e bōpehile ka har'a tube e sekoti.Peipi e se nang moroallo e phethoa ho ea ho litekanyo tsa botenya le lebota ka boholo ho tloha ho 1/8 inch ho isa ho 32 inch OD.Carbon Steel Seamless Pipes / Tubes Carbon steel ke motsoako o nang le tšepe le khabone.Peresente ea carbon ka tšepe e ama ho thatafala, matla a elasticity le ductility ea carbon steel.Pipe ea tšepe e se nang seamless kapa ingot ea tšepe e tiileng e entsoe ka tube ea capillary ka lesoba, ebe ka mohala o chesang, o batang kapa o batang o etsoa.Seamless carbon steel pipe indastering ea tšepe ea China e na le boemo ba bohlokoa.Seamless carbon steel pipe material is the round tube, lipeipi tsa mochini o sehang mahe a emolisitsoeng ho feta ho khaola hoo e ka bang 1 m ea bolelele bo se nang letho, 'me e romelloa ka ho futhumatsa sebōpi sa conveyor.Billet e kenngoa ka seboping sa ho futhumatsa, mocheso o ka bang likhato tse 1200 tsa Celsius.Mafura ke hydrogen kapa acetylene.Taolo ea mocheso oa sebōpi ke taba ea bohlokoa.Roala tube e ile ea tsoa ho phunya mochini ka har'a khatello ea moea.Ka kakaretso punch e atileng haholo ke mochini oa "tapered roll perforation", "punch" e phahameng ea tlhahiso, boleng ba sehlahisoa, katoloso e kholo ea lesoba, e ka roala tšepe e fapaneng.Perforation, tube e chitja e 'nile ea e-ba holim'a li-roll-roll cross rolling, rolling kapa extrusion.E petelitsoe ka har'a tube ka mor'a hore boholo bo be teng.Ho cheka mekoti ka lebelo le phahameng la rotary cone ka har'a billet ho etsa tube.Pipe bophara ka leloala sa size ho fumana bolelele ba bophara ba boro.Ka mor'a hore pipe e kene ka har'a tora e pholileng, ho pholile ka metsi, tšepe ka mor'a ho pholile, e lokela ho otloloha.Ka mor'a lebanta la tšepe le rometsoeng ka ho otlolla mochine oa ho hlahloba tšepe (kapa teko ea khatello) bakeng sa tlhahlobo ea ka hare.Haeba phala e ka hare e phunyeha, li-bubble le mathata a mang a tla fumanoa.Ka mor'a phala empa hape ka mokhoa o thata oa ho laola boleng ba bukana.Boleng ba tšepe, tšebeliso ea linomoro tsa pente ea spray, litlhaloso, palo ea lotho ea tlhahiso.Ka krene e kenang ntlong ea polokelo.

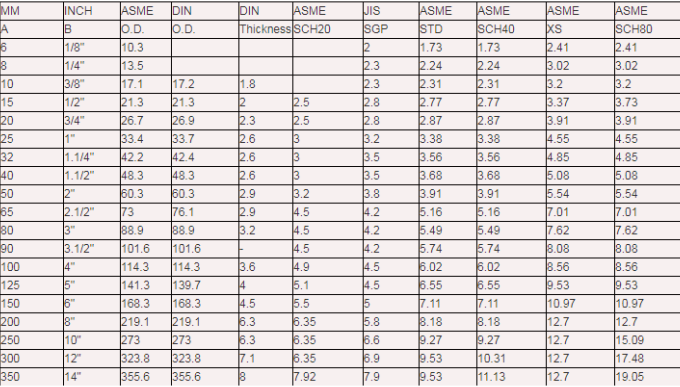

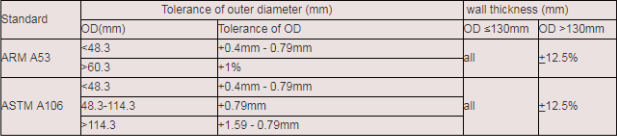

Botenya ba lerako la phala e se nang moeli

Ho mamella bophara ba ka ntle le botenya ba Lerako

Tlhaloso

| Standard | Tlhaloso |

| ASTM A179/A179M | Mocheso o batang o se nang seamless o huleloang ka tšepe e tlase ea alloy le li-tubes tsa condenser. |

| API 5L | Pipe ea mela. |

| ASTM A53M | Pipe ea Tšepe e Khōlō e Tletseng e Tletseng le Zinc e Tletseng, e Seamless. |

| ASTM A106M | Seamless carbon steel pipe bakeng sa tšebeletso ea mocheso o phahameng. |

| ASTM A105M | Lisebelisoa tsa tšepe tsa carbon bakeng sa lisebelisoa tsa liphaephe. |

| ASTM A234M | Lisebelisoa tsa liphaephe tsa tšepe e entsoeng ka carbon le alloy steel bakeng sa tšebeletso ea mocheso o itekanetseng le o phahameng. |

Standard

| Standard | Mofuta oa phala | Sehlopha | Kereiti |

| API SPEC 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q , L485Q X70Q | ||

| Tikoloho e Bolila ea PLS2 | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS | ||

| MOFISA | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, |

| Standard | Kereiti |

| ASTM A 53 M | A, B |

| ASTM A 106M | A, B, C |

| JIS G3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

Kereiti: Sebopeho sa Lik'hemik'hale (%):

| Standard | Kereiti | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| ASTM A 106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| JIS G3454 | STPG 370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| Tlhaloso: STPG 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| JIS G 3455 | STS 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| Setšoantšo sa ST410 | ≤0.30 | 0.10-0.35 | 0.30-1,40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| Setšoantšo sa ST480 | ≤0.33 | 0.10-0.35 | 0.30-1,50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| JIS G 3456 | Setšoantšo sa 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| Setšoantšo sa 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| Setšoantšo sa 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Ho penta & Coating

Phekolo ea holim'a phala ea tšepe: E le ho ntlafatsa bophelo ba tšebeletso ea liphaephe tsa oli, phekolo ea holim'a metsi e atisa ho etsoa ho thusa ho tiisa motsoako oa phala ea tšepe le li-anticorrosive coating. mekhahlelo e mene.

1.Cleaning Grease, lerōle, lubricant, lintho tse phelang tse khomaretsoeng holim'a phala ea tšepe, hangata li sebelisa solvent, emulsion ho hloekisa holim'a metsi. kahoo mekhoa e meng ea phekolo e hlokahalang.Thuso ea mafome ea ho tlosa Peipi ea tšepe holim'a oxide, mafome, slag ea welding, e ka sebelisa borashe ba tšepe ea tšepe ho hloekisa le ho bentša phekolo ea holim'a metsi.

2.Tool derusting e ka aroloa ka letsoho le matla, sesebelisoa sa letsoho sa letsoho se ka fihla boemong ba Sa 2, sesebelisoa sa matla se ka fihla boemong ba Sa3. Haeba holim'a phala ea tšepe e khomaretsoe ka letlalo la oxide le matla haholo, ho ka 'na ha se ke ha khoneha ho e tlosa. mafome ka thuso ea lisebelisoa, kahoo re hloka ho fumana litsela tse ling.

3.Pickling Mekhoa e tloaelehileng ea ho khetha e kenyelletsa k'hemistri le electrolysis.Empa feela ho khethoa ha lik'hemik'hale ho sebelisoa bakeng sa tšireletso ea pipeline corrosion.Pickling ea lik'hemik'hale e ka finyella tekanyo e itseng ea bohloeki le ho ba mahlahahlaha holim'a phala ea tšepe, e loketseng melapo ea ankora e latelang. ho thunngoa (lehlabathe) ka mora ho ntlafala.

4. Ho phatloha ho hoholo bakeng sa ho tlosa mafome. Ka matla a phahameng a motlakase a khanna li-blades tse potolohang ka lebelo le phahameng, grit ea tšepe, sethunya sa tšepe, karolo, liminerale le terata e 'ngoe e senyang tlas'a ts'ebetso ea matla a centrifugal holim'a spray ea tšepe holim'a peipi le ho ntša boima, tlosa ka botlalo. mafome, oxides le litšila ka lehlakoreng le leng, ka lehlakoreng le leng, tšepe phala tlas'a ketso ea abrasive tshusumetso e mabifi le matla a khohlano, ho finyella e hlokehang junifomo roughness.Har'a mekhoa e mene ea phekolo, thunya ho phatloha le derusting ke mokhoa o loketseng oa phekolo bakeng sa ho senya lipeipi.Ka kakaretso, ho thunngoa le ho senya li sebelisoa haholo-holo bakeng sa phekolo ea ka hare ea holim'a phala ea tšepe, 'me ho thunya le ho senya li sebelisoa haholo-holo bakeng sa phekolo ea ka ntle ea phala ea tšepe.

Packing&Loading

Fafatsa pente

Sephutheloana se sa keneleng metsi